Expansion Joints

Expansion joints are components of industrial piping systems designed to accommodate axial, lateral, and angular movements. Their primary function is to absorb movements caused by thermal expansion. Based on their materials, expansion joints are classified into metal, rubber, and fabric types.

Our skilled professionals in the manufacturing facility are dedicated to producing high-quality products. Expansion joints are designed based on on-site surveys or the information provided. Our company also undertakes the installation of the manufactured expansion joints on-site, with references from key industry players both in Hungary and abroad. We are fully equipped to handle all necessary related tasks during replacement, including the use of cranes, hoisting equipment, scaffolding, or any other tools essential for the replacement process. Therefore, we can confidently say that our company supports clients throughout the entire process—from design to final installation. The biggest advantage of this approach is that the client does not need to invest unnecessary effort in coordinating workflows, and all warranties related to the work are consolidated in one place.

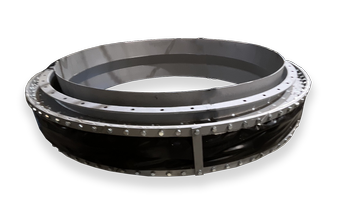

In addition to fabric expansion joints, our company also supplies rubber, steel, and stainless steel expansion joints, striving to meet all our customers’ needs promptly and with the highest quality.

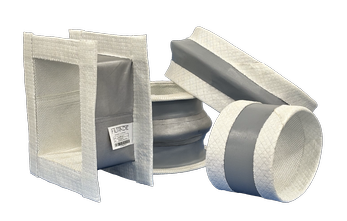

The fabric expansion joints manufactured by our company are available to customers in an exceptionally wide range of materials and temperature ratings, tailored to the required shapes and sizes. Our products are suitable for conveying neutral, alkaline, acidic, and abrasive media, and can be produced to withstand temperatures exceeding 1000 °C, all customized according to customer specifications and often with very short delivery times.

Our skilled professionals in the manufacturing facility are dedicated to producing high-quality products. Expansion joints are designed based on on-site surveys or the information provided. Our company also undertakes the installation of the manufactured expansion joints on-site, with references from key industry players both in Hungary and abroad. We are fully equipped to handle all necessary related tasks during replacement, including the use of cranes, hoisting equipment, scaffolding, or any other tools essential for the replacement process. Therefore, we can confidently say that our company supports clients throughout the entire process—from design to final installation. The biggest advantage of this approach is that the client does not need to invest unnecessary effort in coordinating workflows, and all warranties related to the work are consolidated in one place.

In addition to fabric expansion joints, our company also supplies rubber, steel, and stainless steel expansion joints, striving to meet all our customers’ needs as efficiently and promptly as possible.

Types of Expansion Joints

Below you can find an overview of our main product categories, providing insight into the solutions we offer across various industrial sectors. Within each category, we design and manufacture fabric expansion joints in any shape, configuration, and size to meet specific requirements.

High-temperature expansion joints

Optionally equipped with thermal insulation

Maximum temperature: up to 1000°C

High thermal insulation, low heat loss

Application: cement plants, asphalt plants, power plants, metallurgy

Expansion joints for acidic and alkaline media

Made from PTFE-coated fabrics

High chemical resistance (pH 0–14)

Easy to clean, virtually non-stick surface

Available in single or multiple layers (for increased wear resistance)

Temperature resistance: -150°C to +260°C

Application: chemical industry, biomass power plants, food industry, pharmaceutical industry

Bellows or corrugated expansion joints

Single or multiple convolutions

With steel ring reinforcement (e.g., for vacuum applications)

Application: equipment operating under high vibration and oscillation

High wear-resistant expansion joints

Maximum temperature: up to 1000°C

Wear resistance can be enhanced with an internal deflector plate

Application: cement plants, agricultural facilities, mining, food industry, etc.

Expansion joints resistant to high mechanical stress

Maximum temperature: up to 1000°C

Also available with metal fiber reinforcement

Application: equipment operating under high vibration and oscillation, fans

Food-Grade (FDA-Compliant) Expansion Joints

Can be integrated into EPH systems

Made entirely of conductive fabrics

Available in acid- and alkali-resistant, as well as food-grade versions

Application: air duct and material transport systems where electrostatic charging/discharging may occur (e.g. food industry, wood industry, chemical industry, etc.)

Electrically Conductive and Groundable Expansion Joints

Connectable to the EPH (Equipotential Bonding) Network

Made from fabrics that are electrically conductive through their entire cross-section

Also available in acid- and alkali-resistant versions, as well as food-grade designs

Application: ductwork and material handling systems where electrostatic charging/discharge may occur (e.g., food industry, woodworking, chemical industry, etc.)

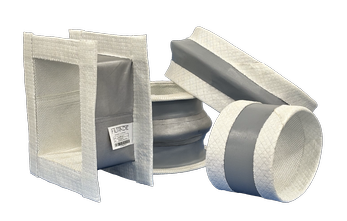

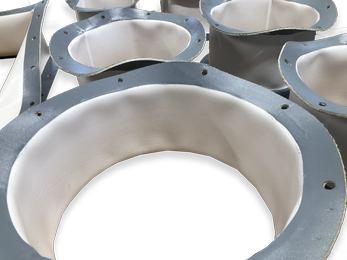

Expansion Joint Accessories

Design and Manufacturing of Custom Deflector Plates and Clamping Flanges

Deflector Plates: available in carbon steel, stainless steel, or wear-resistant versions

Design and Manufacturing of Mounting Frames and Support Structures for Fabric Expansion Joints Manufacturing and Distribution of Expansion Joint Clamps and Straps

Application: improving wear resistance, heat resistance, and thermal insulation,reduction of Condensation

Distribution of Steel Expansion Joints and Rubber Expansion Joints

Contact Us!

If you have any questions,

feel free to get in touch with us.